Chorded keyboard is a computer keyboard where you get characters by pressing several keys at the same time.

This input method should improve speed, make your keyboard one hand usable, smaller and mobile or just make you look like ultra cool elite hax0r.

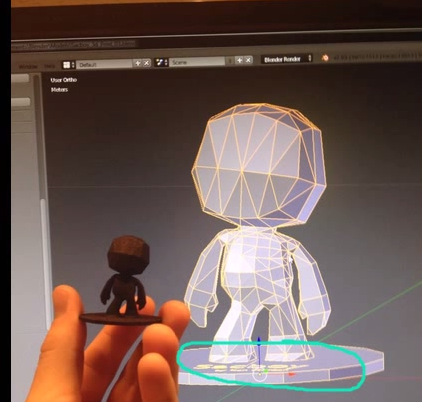

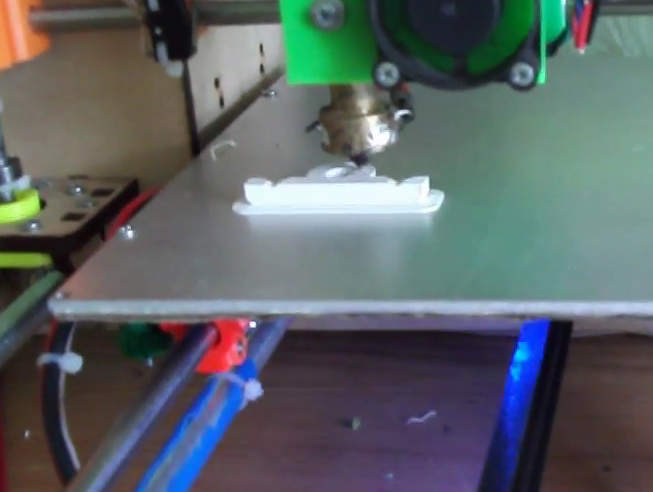

There are many different projects and now there is a Chordy KEY project with 3d printable case.

Project homepage on hackadayio :

https://hackaday.io/project/2115

GitHub repostiory with all the details and STL files:

https://github.com/Madfellows/Arduino/tree/master/Chording%20keyboard

From project description:

For standard 3d printed keyboard look at:

http://diy3dprinting.blogspot.com/2015/03/photo-log-of-3d-printing-fully.html

New chorded keyboard project:

http://diy3dprinting.blogspot.com/2015/12/3d-printable-chording-handheld-keyboard.html

This input method should improve speed, make your keyboard one hand usable, smaller and mobile or just make you look like ultra cool elite hax0r.

There are many different projects and now there is a Chordy KEY project with 3d printable case.

|

Chordy KEY combinations. Well, there is a learning curve if you want to be cool ... |

Project homepage on hackadayio :

https://hackaday.io/project/2115

GitHub repostiory with all the details and STL files:

https://github.com/Madfellows/Arduino/tree/master/Chording%20keyboard

From project description:

Chording keyboards have been around for a while, but appear to not be taken seriously. Although you can see many data entry methods throughout science fiction but usually involve hundreds of buttons that require the user to look at them and appear to be hard to work in adverse conditions or with bulk such as gloves.

The chording keyboard can take on many different shapes and easily used with one hand. The keys can be easily acquired without the use of pips and build with proper spacing to be used with gloves. The lower amount of keys used makes the manufacturing of the device cheaper and simpler.

This project is a completed left hand proof of concept chording keyboard that currently has all functionality of a standard keyboard minus function keys and plenty of combinations to add them and many macros. The base microcontroller is a ATmega32U4 packaged as a sparkfun pro micro, 8 buttons and 6 indicating leds the case is 3d printed and backed with craft foam.

For standard 3d printed keyboard look at:

http://diy3dprinting.blogspot.com/2015/03/photo-log-of-3d-printing-fully.html

New chorded keyboard project:

http://diy3dprinting.blogspot.com/2015/12/3d-printable-chording-handheld-keyboard.html